As a manufacturer of consumable goods, it’s important to make sure that your products are not only safe to eat or drink but also provide the most satisfaction to customers. Doing well in maintaining and improving the quality of the food or beverages you sell can benefit your brand in many ways.

People who love what you sell are guaranteed to stay with your brand. Attaching quality to your name ensures that your business is trusted when it comes to manufacturing foods that plant a legacy.

If you want your brand to endure like the most successful names in the food industry, focusing on ensuring the quality of your products is the best place to start. Here’s a guide to help you with that:

Make Quality Your Mantra

You can’t produce anything of high quality if your business doesn’t live by that principle. Once it becomes a part of your brand identity and your business’s philosophy, then it becomes the reason for your entire operation. For this reason, start by reviewing your business plan and include verbiage that shows how you want to incorporate quality in your products.

Once you have revised your business plan to reflect your commitment to quality, you can mention this thrust in every marketing material you have. Mentioning quality can only do so much to let customers know your focus. The real challenge is knowing how to put theory into practice by realizing the quality of the products you’re selling.

Use Healthier Processes

Most people can tell the difference between foods that are manufactured with quality in mind and foods that are made with love and care.

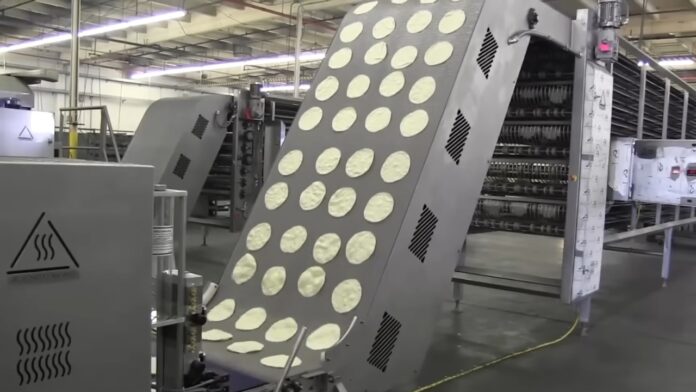

All this boils down to the processes that are used in manufacturing food. Mass production often causes the loss of nutrients and flavors. Resorting to artificial ingredients such as preservatives can also cause quality to deteriorate.

Fortunately, some approaches can help preserve the flavors of your products and create a gastronomic experience your customers will love. Traditional cooking methods may take time, but it’s a good reason why many of the best brands are the ones that do not rely entirely on mechanized processes. It also helps if you use a food dehydrator to help extend the shelf life of your products without the need for preservatives.

Whenever possible, your production process should always make use of traditional methods that make a difference in terms of taste and nutrition. Using brick ovens and utensils made from natural materials effectively improves the quality of your products.

Order Organic Ingredients

Going back to using preservatives, you shouldn’t use too much just to extend the shelf life of your products. If quality is your main priority, you must rely on safer and all-natural preservatives. Now that consumers are fully aware of the dangers of MSG and sodium nitrite, it won’t help if your products contain too many of these preservatives and additives.

Quality food doesn’t need additional chemicals to taste better and last longer. There are all-natural ingredients out there that can be used to enhance the flavor of your products. Ginger and citric acid can do well in making food more savory. Certain herbs and spices and even oyster sauce can be great replacements for MSG if you’re looking for an all-natural seasoning.

It’s always a good idea to invest in research that will help you find better, safer, and healthier alternatives to conventional additives. This will also help set your business apart from competitors who might still be using chemicals.

Use the Right Quality Assurance Tools

No consumer would eat something that contains traces of plastic and metal. The purity of your products adds to their quality, so failing to detect unwanted debris will reflect badly on your brand.

Even worse is when consumers start to fall ill and blame your products for causing food poisoning, stomach cancer, and other conditions that are caused by foreign objects embedded in your products. Preventing this requires using the right equipment that can aid in detecting impurities and ensuring your products are safe to eat before reaching the supermarket shelves.

For instance, it helps if you can invest in product testing tools such as a food X-ray meant to detect small metallic particles in every product that passes the production line.

An article from TDI Packsys doubles down on why you need technologies such as this particularly if you’re involved in canning sardines and other fish products.

Your business should also adopt the guidelines on physical and chemical testing procedures to ensure your product passes FDA standards. This alone gives consumers confidence that you’re committed to providing quality goods as you promise in your company vision and mission.

Ensure Cleanliness at Your Plant

The worst thing your customers want is to find a strand of hair in a tub of ice cream. Even if your products come out pure, cleanliness still has a significant impact on quality. When you have workers who don’t follow basic rules on hygiene and kitchen management, the chances of contamination increase. This will not only affect the taste and longevity of your products but it can also lead to food poisoning.

Preventing food contamination is a responsibility shared by everyone on the production floor. Setting up strict guidelines in the handling of ingredients as well as accessing food preparation facilities can help preserve the quality of your products.

Regular food safety training sessions will ensure that your products are free from bacteria, germs, and debris before leaving the production floor. Regular checks can also help in ensuring compliance with sanitation standards.

Cleanliness is as basic as it comes, but considering that it has a direct impact on food quality, you will want to make sure your manufacturing plant is kept spic and span.

Invest in Innovation

Innovation is at the center of the food industry where the best brands are those that learn how to offer new product lines. More than that, it’s how you improve current products that guarantee your success.

For your products to achieve a timeless character, find ways to improve their taste and nutritional value. Aside from adding new variations, you can enhance your current line of food items using new ingredients. That way, people familiar with your brand are provided with a newer and better experience.

Endnote

As someone active in the food manufacturing industry, quality is a priority. Even if you’re manufacturing frozen foods or potato chips, providing only the best for your customers is the only way to survive in this highly saturated sector.